10 Reasons to Use Iron Ore Pellets in Your Construction Industry

Iron ore pellets are an effective and efficient way to transport ore, especially when compared to the alternative of transporting it in raw form. Iron ore pellets don’t require loading by hand and they can be stacked on top of each other, eliminating the need for forklifts or pallets.

Pellets are also beneficial to the industry as they can significantly reduce shipping times and costs, which reduces the overall cost of your product. When it comes to your industry, make sure you use iron ore pellets. Here are 10 reasons why iron ore production in India is important

1) For Irrigation

Iron ore pellets are very easy to transport, so it is not a concern when a large quantity needs to be delivered. The hardiness of the material is what makes it suitable for this industry.

They are long-lasting, which will save you time and money when you need something that can withstand a lot of weathering. Using pellets means there’s less wear and tear on your equipment because they do not create sharp edges as raw ore does.

2) As Fertilizer

A fertilizer is a natural or synthetic substance applied to soil to supply one or more plant nutrients essential for the growth of plants. When used for this purpose, it is often called an agricultural fertilizer.

3) As Water Treatment

Water treatment facilities are an important part of many constructions, but they can be quite expensive.

Thankfully, there is a low-cost alternative that offers many of the same benefits and it is iron ore pellets. These granules have been used for decades as an industrial material for waterproofing and grouting.

4) As Furnace Fuel

One of the most commonly found uses for iron ore pellets is for industrial furnaces, used as a fuel source.

The pellets are made from scrap iron, and when crushed down into small pieces and pressed together, they create a solid fuel source with higher energy density than coal. And because they’re made from scrap metal from iron ore miners rather than raw ore, they cost less on the front end.

5) In Foundries

Iron ore pellets are one of the most popular ways for foundries to get an adequate supply of iron for melting.

A pellet is created by taking cast iron and crushing it into a small, cylindrical shape. This process is much more efficient than having to wait for ingots, which can take upwards of three months. The pellets can then be crushed into smaller pieces before being melted down.

6) Iron Pellets As Grinding Media

Iron ore pellet manufacturers offer several benefits over other grinding media. They can withstand heavy pressure without fracture, they do not react with chemicals, they do not corrode metal and they are more economical than other types of media.

7) As Ferric Chloride Catalyst

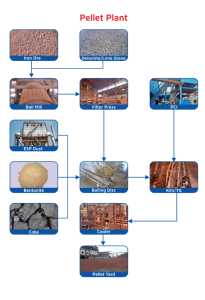

Ferric chloride is a strong chemical that can be used for many different applications. One such application is as a catalyst in the conversion of iron ore pellets into liquid and slag.

This process starts with an ore loading unit which pours out a charge of oxygen into the converter before charging it with powdered ore from either pellet or lump form. Then, molten pig iron is tapped from the end of the furnace, cooled, and cast into slabs for shipment.

8) In Blast Furnaces

Iron ore pellets are used as an alternative fuel source for blast furnaces. They can be stored and loaded at ground level, which makes them easy to transport. Plus, it’s cheaper and more environmentally friendly than coal.

9) For Road Construction

Iron ore pellets may seem like an unimportant and unrelated topic. However, it is a very important one, especially for the construction industry. Metal pellets are a cost-effective way of constructing paved roads with high compressive strength and good resistance to erosion.

10) As Golf Course Greens Fertilizer

Golf course greens use a significant amount of fertilizer and sometimes the need for too much iron becomes an issue. This is where iron ore pellets come into play. They’re a good source of supplemental iron when other sources of readily available iron become scarce.

Iron ore pellets are cheaper, more versatile, and more durable than other forms of supplementary such as liquid or dust concentrates. It’s also relatively easy to monitor how much is used as opposed to something like liquid fertilizers. Which can evaporate and may not be measurable until after it’s too late.

When managing some greens you have full control over fertilization rates which is another major pro when using pellets rather than organic products that don’t provide this capability.

Conclusion

Iron ore pellets are an increasingly popular alternative to the concentrate one for the steel industry. Because they tend to be less expensive, more environmentally friendly, and easier to transport.

They are also safer to handle than iron ore concentrate since they are solid instead of slurry. These are ten reasons why you should use iron ore pellets in your industry today! Visit our website to know more!